Blog #3

Remote-Controlled Garden Seeder

Team 31- Beyza Kural, Syed Hussain, Nawaf

Abulhaija

Progress Update 10/28-11/11:

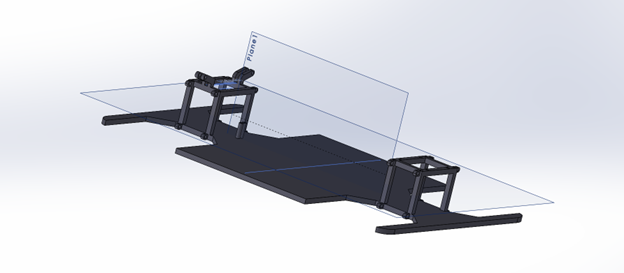

During the work period of

October 28-November 11, our team has been working on completing the analysis phase

of our device as well as finishing up designing the parts in SolidWorks so that

we can complete the full assembly before November 15, 2023. Our milestones 1-3

are completed and we have conceptualized our design with all the parts

selected. We completed some preliminary sketches for the design and settled on

a design that utilizes a top loaded motorized hopper with an aerator in front. The

preliminary sketch of the device can be seen below.

The chassis of the device

includes spacing for large diameter wheels, the suspension system, and adequate

space in the center for both the servo motor, which will be used to control the

front tires and allow left/right movements, and a brushless electric motor on

the rear tires to help the forward and backward movement. The motor will be

connected to a set of gears that will help increase the torque output while

simultaneously decreasing the speed. This will ensure that the power being

transmitted to the wheels will supply enough torque to be able to handle the anticipated

load.

Plan for Near Term Work 11/11-11/25:

During the next 2 weeks,

our team plans to finish the remaining tasks in our 4th major

milestone which is the design phase. We have some tasks that we’re currently

still behind on, so our focus is to get back on schedule. Some of the tasks

include finishing our analysis such as our motor torque calculations, gear

ratios, wheel size selection, and FEA analysis. We will also continue to finish

designing the components of our device. Some of the components may need to be

reworked based on our FEA analysis. Our main frame will also require significant

work since we’re still trying to figure out the best design and placement for

the aerators in the front of the device. We need to also figure out where the

hopper will sit on the device and the dimensions of the hopper that will

optimize its weight distribution while still meeting our minimum parameters.

Lastly, we will need to design the electrical layout of the device and all the

necessary wiring. We expect the device to be assembled by 11/15 and we will

continue to reiterate the design until the end of the semester.

Expected Obstacles:

Some of the obstacles our

team foresees in the next 2 weeks are finishing the design and sourcing all the

parts for it. Originally, we were going to utilize an existing

remote-controlled vehicle to source parts from and then just change the chassis

as needed. However, our team decided to try and build it out from scratch which

means that there will be a lot more parts that are going to have to be custom

designed for our device. We’re going to try and source as many parts as

possible off the shelf but will plan to meet with suppliers during the break to

see if we can have all the parts constructed as soon as possible. Another issue

our team foresees is trying to get back on schedule. With the semester coming

to an end soon, this is usually the time where we will face the most scheduling

challenges with upcoming exams. It is crucial that we finish our first design

iteration by 11/15 as well as the remaining parts of the analysis to ensure

that we will complete our required tasks by the end of the semester. Finishing

the device design by 11/15 will put us back on track and will ensure that the

rest of the work is completed on time. In terms of the parts sourcing, if we struggle

to find parts of the shelf, we may consider scaling our device size down a bit to

be able to use off the shelf parts.

Comments

Post a Comment